The Greatest Guide To 5 Ways You Can Use 3D Printing to Create a Prototype

What Is 3D printing and prototyping? - FuroSystems

The Definitive Guide to World's largest 3D printer speeds up prototyping and

When selecting a 3D printing technology, initially figure out critical design requirements like strength, temperature level resistance, water resistance, aesthetic appeals, or durability. This will typically help you identify if a metal or plastic 3D printing is needed for your application. Take a look at this 3D printing material selection guide for more assistance on technology choices to align with your style requirements.

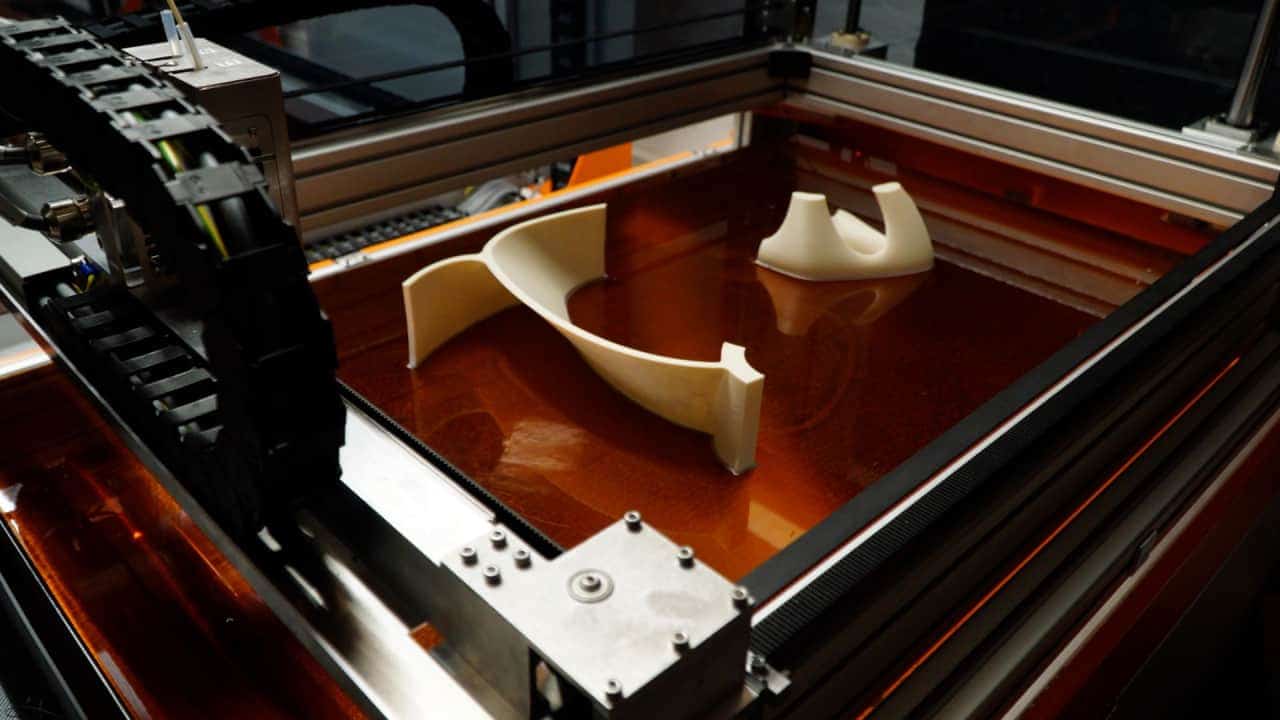

Fast prototyping with 3D printing is the quick, easy, cost efficient way to turn excellent ideas into successful products. Do you need concept modeling to put your most recent concepts to the test? What about practical prototyping to evaluate performance before committing to expensive production tooling? Quick prototyping solutions from Stratasys will offer you the flexibility to create, test and fine-tune in ways you never ever believed possible so you can go to market quicker than ever before.

The Type 3 produces parts with top quality surface finish and fine functions, guaranteeing that your models are created quickly and true to design with very little post processing. Bring industry-quality models internal at an inexpensive price, allowing your group to print new models in a few hours. Use the Form 3 at numerous points of the item advancement procedure for a much faster ROI.

Arup unveils its first 3D-printed structural steel building components

Unknown Facts About How Much Does a Prototype Cost to Make? 3D Printing

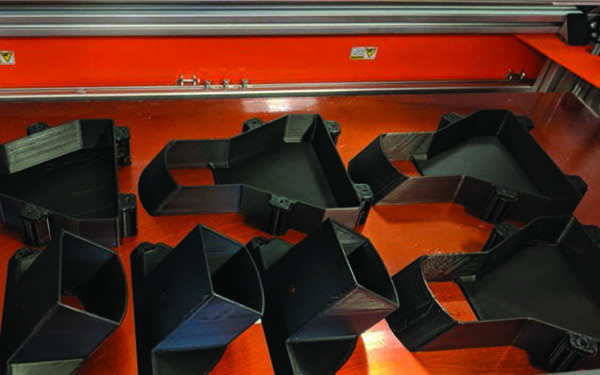

About the 3D Printing Process3D Printing, or additive manufacturing, is a procedure that uses a CAD file (typically an STL) to produce a 3-dimensional part. Find Out More Here are produced layer by layer using a variety of various products and layer adhesion innovations. Types of 3D Printing3D printing has progressed substantially over the decades and in time numerous different technologies have actually been established: is a common process for early stage models.

usages high-powered lasers to sinter powdered material, binding it together to develop a solid structure. This procedure is ideal for practical screening, in the low to mid volumes (10s to 100s of units). is known for achieving highly in-depth and functionally precise parts. The technology utilizes a mirror that is configured to direct an ultraviolet laser to draw and treat a part's cross-section onto a barrel of photopolymer resin.